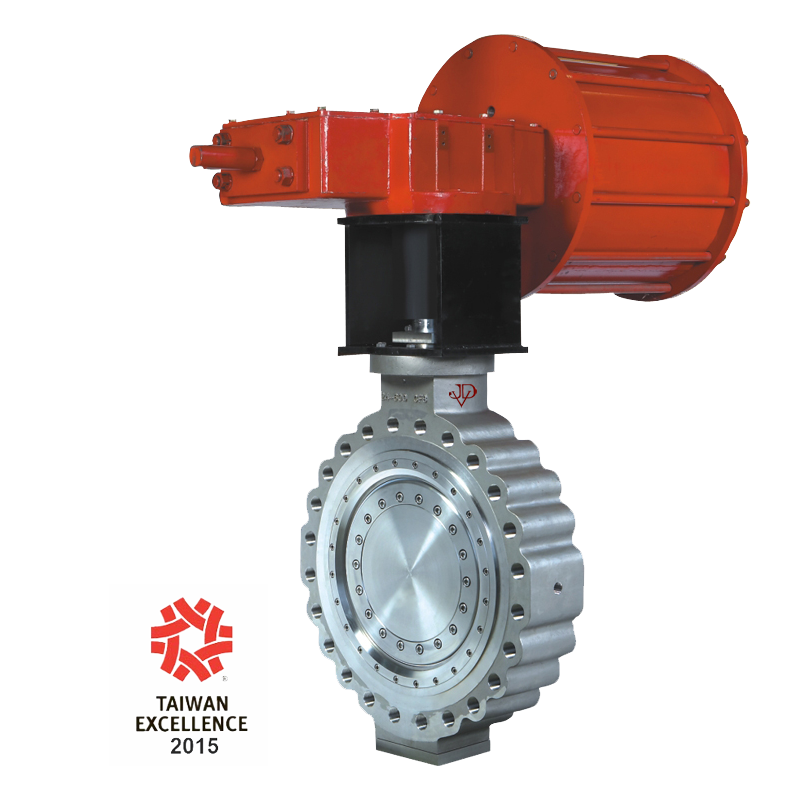

JTEM Series

Triple Offset Metal-Seated Butterfly Valve

Wafer / Lug / Flanged Ends ASME CLASS

150/300/600/900/1500/2500

A revolutionary design of triple offset geometry, a progressive contact angle, an innovative double-inclined seat cone axis, a self-adaptive sealing system and a metal-to-metal sealing are a few examples of the unique features of our JTE triple offset butterfly valve. Especially designed for extreme working conditions such as high temperature, cryogenic temperature, high pressure drop and abrasive mediums, it offers unparalleled performances and zero leakage capability to meet the toughest requirements in the most challenging industries.

Applicable Standards

- Body Material: Standard in WCB, CF8, CF8M. Other materials are available according to requirements.

- Nominal Size: 3” to 24” (DN80 to DN600), 26” to 72” (DN650 to DN1800) are on request.

- Pressure Rating: ASME CLASS 150/300/600, 900/1500/2500 are on request.

- End Connections: Wafer / Lug / Flanged Short Pattern and Long Pattern.

- Temperature Range: -320~932°F (-196~500°C), higher temperature on request.

- Design Standard: API 609 / ASME B16.34 / BS EN 593 / EN 12516

- Flanged Dimensions: ASME B16.5 (NPS 3 to 24) / MSS SP-44 (NPS 12 to 24) / ASME B16.47 (NPS 26 to 60) / ASME B16.47 (MSS SP-44) / ASME B16.47 (API 605) / EN 1092-1 / DIN 2501 / ISO 7005

- Face-to-face Dimensions: API 609 Category B for Lug/Wafer / ISO 5752 for Flanged Short Pattern / ASME B16.10 for Flanged Long Pattern / EN558 Series 16 for Lug/Wafer / Series 13/14 for Flanged Short Pattern

- Anti-blowout Stem Design: Complied with API 609 Sec. 4.9

- Casting: MSS-SP-55

- Marking: MSS-SP-25 / EN 19

- Mounting Pad: ISO 5211

- Screw Thread: ASME B1.1 /BS 3643

- Body Pressure Test: API 598 / ISO 5208 / EN 12266-1

- Seat Leakage Test: ANSI/FCI70-2 Class VI in standard, Zero leakage is available on request.

- Cryogenic Temperature Test: BS 6364

- Fire Safe Design: Certificated according to ISO 10497

- Low Emission Design: Certificated according to ISA 93.00.01 / ISO 15848-1 / VDI 2440 (TA-Luft)

- Functional Safety Certification: SIL3 (EC 61508 Parts 1-7:2010)

Product features

- Solid metal seat and seal ring providing a true metal to metal design that withstands abrasive mediums and the high pressure drop.

- Separate seat design allowing an easy maintenance.

- Revolutionary double inclined design providing:

- Bi-directional in tight sealing

- Light torque.

- A self-adaptive function increasing even further the valve life cycle. The contact point between the seat and the ring move with different working condition and over cycle time, therefore the friction does not always occur on the same contact point.

- Wide range of hard faces to seat and seal ring meeting the requirements of most using conditions.

- Flexible metal seal ring precluding the jamming caused by thermal expansion to ensure a tight and safe sealing.

- 1-PC stem design increasing the strength of the shaft and enhancing the valve life cycle.

- Stem bearings ensuring the stability of the shaft .and extending even more the valve life cycle.

- Live-loading design increasing further an already long life cycle.

- Low emission design with double stem packing preventing any packing leakage, even with the trickiest mediums Emergent injection design in stem provides reliable safety.

- Optional leakage control device allowing the detection and removal of any hypothetical leakage from the packing.

- Emergency sealing injection device on request to restore the sealing integrity, should it be necessary.

- Anti-shear pin design enhancing the resistance of the stem under high drop pressure.

- ISO 5211 Mounting pad.

Certification

- ANSI ISA 93.00.01-1999

- DNV-CECertificate 2017.04.15

- DNV-ISO 9001-2008 Certificate 2017.02.25

- Fire-safe test ISO 10497 3 Edition [ 1 ]

- Fire-safe test ISO 10497 3 Edition [ 2 ]

- Low emission test ISO 15848-1 First Edition 2006

- SIL3

- CRN