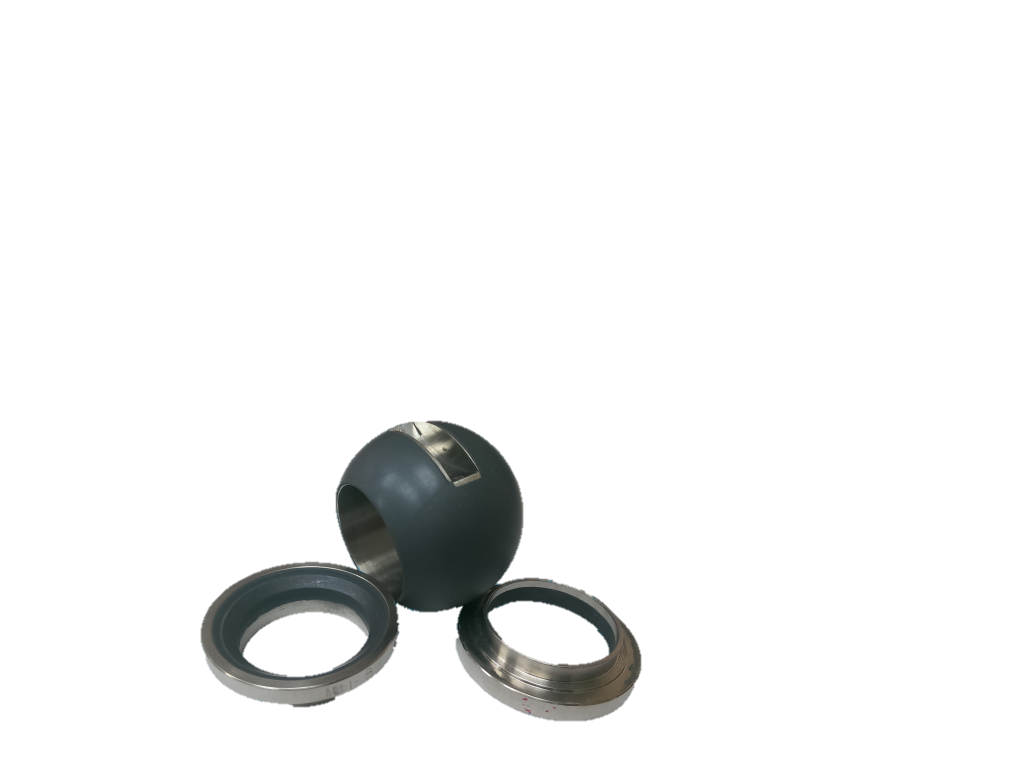

From Aug. 26 to 29 total 4 days, JDV will show its High-Performance valves, leading nationally in the field of High-Performance metal seat in 2015 Taipei Int’l Industrial Automation Exhibition. For the first time , using Titanium Metal Seat technique, JDV applied such high-tech facilities with its unique metal seat skills which not only endure corroding and resist wearing, nut also defend against static electricity. Furthermore, it steps across two new extreme limits in temperature from -253℃ up to 316℃. It is practical for petrochemical industries to apply such unique skills to resolve all their problems. JDV provides industrial safety to a new milestone in Taiwan.

The merits of this “JDV High Performance Valve” include:

(1) It’s extremely excellent corrosion-resistance for its surface was formed a layer of hundreds of strong adhesion of oxide membrane.

(2) Even under the temperature lower than -253℃, it can maintain enough resilience and ductility that is the best material for low temperature manufacturing application.

(3) Its hardness is much better than strengthened structural steel, aluminum alloy, or magnesium alloy.

JDV High Performance valve has been designed an automatic pressure releasing and fire safety. Furthermore, to save operation cost, a speeding convenient replacing process for maintenance is designed so that the idea of Human Engineering is perfectly fit in.

The valve against corrosion, high pressure is completely fitting closely to the solution of environmental protection regulations. Therefore, such High Performance Valve is the best choice to be used in the fields of refining industrial, such as oil, steel, petrochemical, biomedicine, power plant, gas plant, or cremator.

Mr. steven Fan, general manager of JDV, said, “ In order to sponsor this 100% made in Taiwan’s exquisite valve shown in international markets, JDV has been working very hard not only in promotion the quality and service , but also developing branch offices in Switzerland and Singapore.

JDV won 2015 Taiwan Excellence Awards for V-segment control valve, cryogenic control valve and butterfly valve. Products 100% designed and made in Taiwan provide total solutions for your severe applications.

They are:

(1)JSB Series V-Port Segment Control Valve, which has flow control by air dynamic switch , auto-location-fixes design to save human force, it is suitable to be applied for paper plant, oil refining, chemical and petrochemical industrial.

(2)JBF/JBFM Cryogenic Series Floating Soft/Metal Seat Ball Valve ,the product range from +800℃ to -196℃. It is suitable to be applied for industries under critical operational environment. It’s the best choice to be applied for gas, petrochemicals, chemical engineering, power manufacturing, mining, etc.

(3)JTE Series Triple Offset Metal Seated Butterfly Valve, which is high performance with the idea of environmental protection. Its quality runs neck to neck with Euro-American high level valves. The design emphasizes the seat of the valve to be easily maintained, therefore, it can not only shorten maintenance time, but also save human force.

JDV will show the latest “Titanium metal seat Ball Valve” and related products on Aug. 26~29,(Booth No: N418), Taipei Int’l Industrial Automation Exhibition. See our website:www.jdv.com.tw